Piping Systems

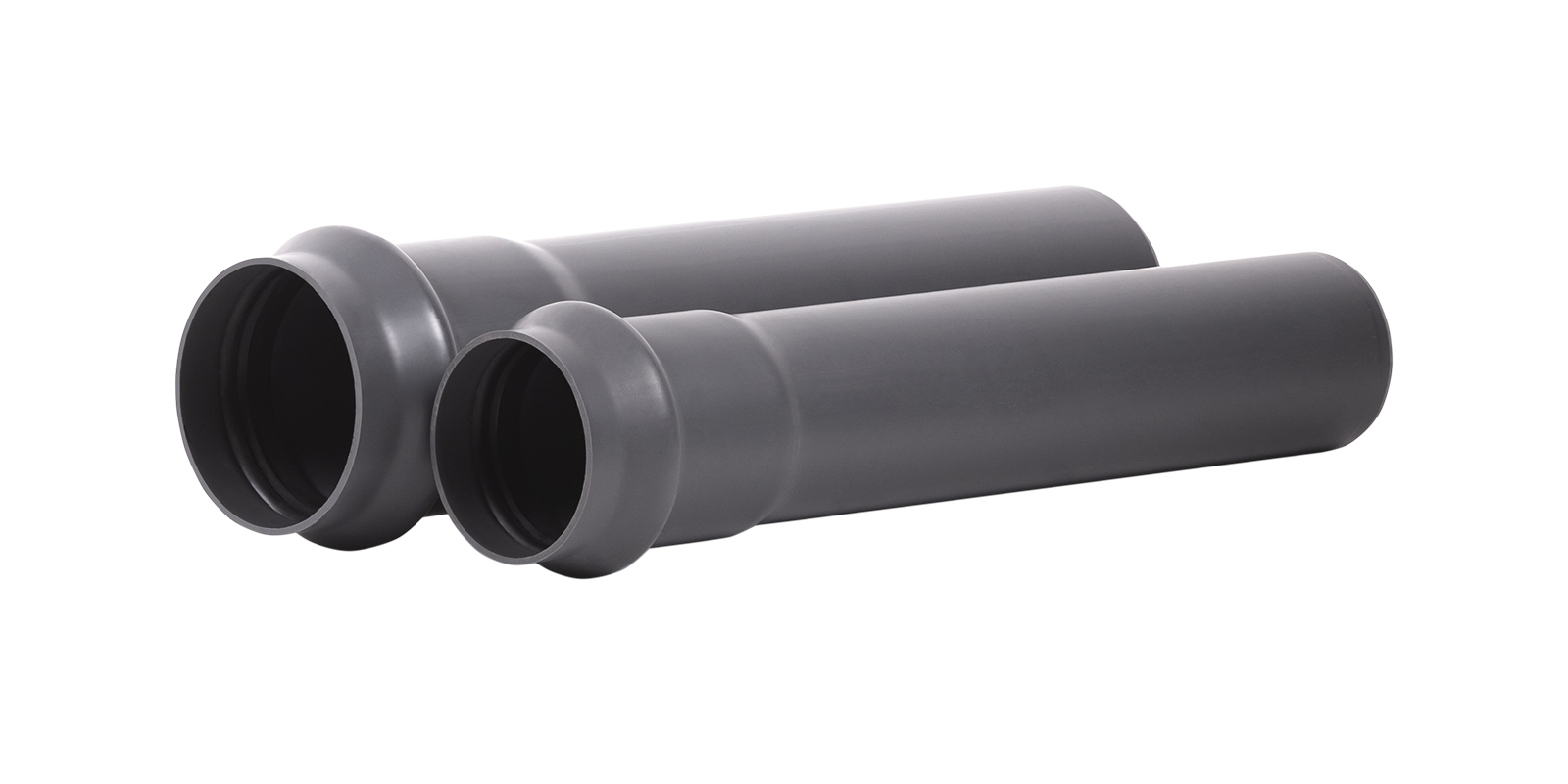

HDPE Pipes PE100

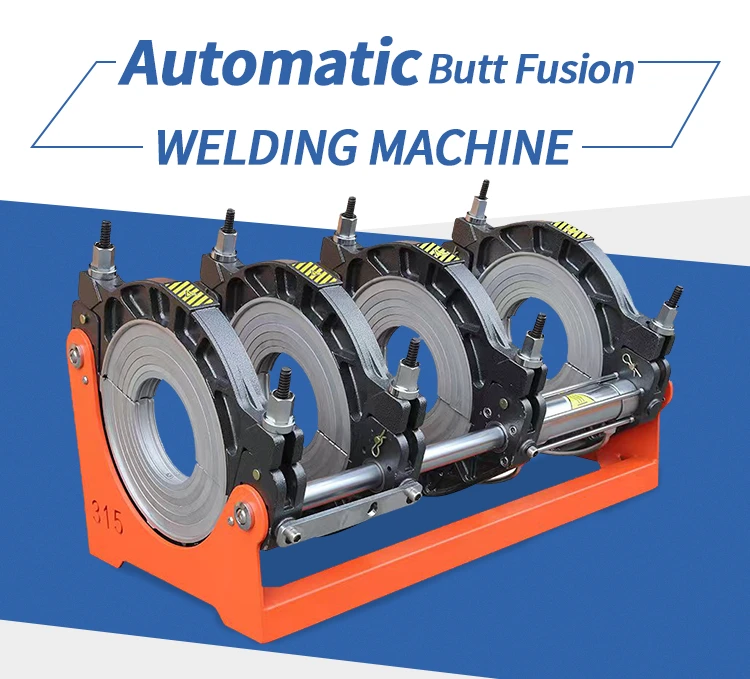

High-quality pipes manufactured from premium-grade high-density polyethylene (PE100), specifically engineered to meet the demanding requirements of modern infrastructure projects. These pipes are designed for the safe and efficient transportation of potable water, natural gas, and other pressurized fluids, making them an excellent choice for municipal networks, industrial applications, and agricultural irrigation systems. Produced under strict international standards, PE100 pipes are known for their exceptional mechanical strength and durability. Unlike traditional piping materials such as steel or concrete, they are highly resistant to chemical attack, rust, and electrochemical corrosion, ensuring consistent performance even in aggressive soil conditions or when exposed to harsh environmental factors. This corrosion resistance significantly reduces maintenance costs and extends the overall service life of the system. One of the defining advantages of PE100 pipes is their outstanding flexibility and impact resistance. They can withstand ground movements, seismic activity, and pressure fluctuations without cracking or leaking. Their flexibility allows for easy installation in challenging terrains, including rocky landscapes, unstable soils, or areas where trenchless technology (such as horizontal directional drilling) is required. This adaptability not only simplifies construction but also minimizes environmental disruption during installation. With a tested and proven lifespan that exceeds 50 years, PE100 pipes provide long-term reliability and cost efficiency. Their smooth internal surface minimizes friction losses, ensuring excellent hydraulic performance and reduced energy consumption for pumping. In potable water applications, the material guarantees safety and hygiene, as it does not affect taste, odor, or water quality. For gas distribution, PE100 pipes provide superior resistance to crack propagation and offer secure, leak-free operation under high-pressure conditions. Furthermore, these pipes are lightweight compared to metallic alternatives, making transportation, handling, and installation significantly easier and more economical. They can be joined using modern fusion welding techniques—such as butt fusion and electrofusion—resulting in a fully leak-proof monolithic pipeline system with joints as strong as the pipe itself. This welding integrity makes PE100 pipes particularly well-suited for high-pressure networks where safety and reliability are paramount. In summary, PE100 high-density polyethylene pipes represent a modern, efficient, and future-proof solution for water supply networks, gas distribution systems, and a wide range of industrial and agricultural applications. Their combination of long service life, corrosion resistance, high flexibility, and excellent hydraulic performance makes them a preferred choice for engineers, contractors, and utility providers worldwide who are looking for both performance and value.

| Technical Specs for (EN) | 45 |

|---|